Hardly tough conditions, but still nice to be out. The Land Rover was well up to the -12 C wind chill and windy conditions, and was both warm in the cabin plus the windows didn't fog up! Used the vehicle in 2-wheel and 4-wheel drive, and even did a little low-range just to give it some excercise.

Yes, there's a red "reindeer" nose on the radiator muff. There were pretend antlers on the roof, but they wouldn't stay on. Will have to find another way. :)

This is just a simple pictorial history of my restoration of an original Canadian-import 1960 Land Rover Series 2 88" (or SWB - Short Wheel Base), LHD (Left Hand Drive) which I purchased in August, 2010. Later posts include photos of some of the things I've done with the vehicle since its restoration was essentially completed, although repairs and other maintenance are obviously an ongoing process. Words in orange are links. Click the photos to make them full size. Search using box below.

Search This Blog

Saturday, December 22, 2012

Sunday, December 16, 2012

Electrical Brake Light Switch Kit

The brake-line pressure-actuated brake lights have been difficult to get working smoothly. Although it's a simple mechanical pressure switch on the line, I could only get the brake lights to work easily if the brakes were badly adjusted, for some reason. If the brakes were (and are) correctly adjusted and working as they should, it took a lot of pressure on the brake pedal to get the brake lights to come on. Don't ask me why. As the Land Rover doesn't need a lot of pressure on the pedal to stop, the brake lights were never on.

This being a safety issue, and not wanting to replace the pressure switch (which would not be an easy job in any case, what with awkward access and draining the system, etc.) without being able to know in advance if the replacement would solve the problem, a work-around was needed. I contacted the ever-helpful Peter at 3 Brothers Classic Rovers (and no, I don't work for them), and he put together what has turned out to be an excellent and simple to install electric brake light kit, consisting of a steel bracket and switch.

The kit requires no new holes be drilled, so the Land Rover can revert to standard original configuration in just a few minutes by taking off the bracket and remove the wiring. This is a real 'plus'.

The only things I had to supply myself was the wiring (and I opted for correctly coloured braided cable, from Autosparks), the connectors, two wire clamps, and one rubber grommet to let the wires go through where there was a plug previously.

Pictured below, the basic layout. Essentially, there's the well-made and position-adjustable steel bracket, through which passes the pedal return spring, and into which the brake switch itself is installed. The switch's body position is also adjustable, forwards and back, and so it's easy to imagine the installation can be made to match any brake pedal setup. Installation was just done by taking out and re-installing two of the six bolts connecting to the brake pedal box. The bracket first appeared somewhat large, but it turns out to be perfectly sized and it stays well away from my foot on the pedal - and is not visible from the driving position.

The switch, as it attaches to the bracket. One nut on the pedal side holds the switch in place. There were several spacers, so the switch button could be exactly positioned against the pedal arm.

Here, the switch button can be seen pushed in by the pedal. As the pedal is pushed, it releases the button, and the brake lights come on. Very simple.

Then, its just a matter of routing the wires through the bulkhead and down to the original pressure switch, attaching them directly to the connection points already there, leaving the original wires also attached. Again, very simple. The electrical switch takes over from the completing the circuit from the pressure switch, lighting up the brake lights. Here, you can just see the new green wires passing under the black bundled wires on the firewall.

And finally, just an illustration of the clearance between bracket and a large boot. With ordinary shoes, etc., there's obviously even more room. The bracket is very stiff, and certainly won't be effected if a boot should come in contact, in any case.

This being a safety issue, and not wanting to replace the pressure switch (which would not be an easy job in any case, what with awkward access and draining the system, etc.) without being able to know in advance if the replacement would solve the problem, a work-around was needed. I contacted the ever-helpful Peter at 3 Brothers Classic Rovers (and no, I don't work for them), and he put together what has turned out to be an excellent and simple to install electric brake light kit, consisting of a steel bracket and switch.

The kit requires no new holes be drilled, so the Land Rover can revert to standard original configuration in just a few minutes by taking off the bracket and remove the wiring. This is a real 'plus'.

The only things I had to supply myself was the wiring (and I opted for correctly coloured braided cable, from Autosparks), the connectors, two wire clamps, and one rubber grommet to let the wires go through where there was a plug previously.

Pictured below, the basic layout. Essentially, there's the well-made and position-adjustable steel bracket, through which passes the pedal return spring, and into which the brake switch itself is installed. The switch's body position is also adjustable, forwards and back, and so it's easy to imagine the installation can be made to match any brake pedal setup. Installation was just done by taking out and re-installing two of the six bolts connecting to the brake pedal box. The bracket first appeared somewhat large, but it turns out to be perfectly sized and it stays well away from my foot on the pedal - and is not visible from the driving position.

The switch, as it attaches to the bracket. One nut on the pedal side holds the switch in place. There were several spacers, so the switch button could be exactly positioned against the pedal arm.

Here, the switch button can be seen pushed in by the pedal. As the pedal is pushed, it releases the button, and the brake lights come on. Very simple.

Then, its just a matter of routing the wires through the bulkhead and down to the original pressure switch, attaching them directly to the connection points already there, leaving the original wires also attached. Again, very simple. The electrical switch takes over from the completing the circuit from the pressure switch, lighting up the brake lights. Here, you can just see the new green wires passing under the black bundled wires on the firewall.

Seen head on, from a lower perspective. The switch assembly is actually invisible when you are seated.

And finally, just an illustration of the clearance between bracket and a large boot. With ordinary shoes, etc., there's obviously even more room. The bracket is very stiff, and certainly won't be effected if a boot should come in contact, in any case.

Saturday, December 8, 2012

Radiator Muffs

As the cold weather is here (well, not too bad yet, but definitely chilly) it seemed the right time to install a radiator muff in order to keep the engine temperatures up.

3 Bros, kindly supplied two versions to try. The first was from Rovers North, the second from Britpart. In the end, I chose the Britpart one.

Both will do the job. The Rovers North one is of somewhat higher quality, but more difficult to install and remove, and I could see the fabric being difficult to clean if necessary. The Britpart one was very easy to install, just requiring some tie-wraps (one set of which comes with the muff, and are cheap to purchase afterwards in any case), and the vinyl surface will be easy to keep clean. The Rovers North muff provides more choices of opening sizes, but the adjustable flap folds and hangs down over and against the apron, which looked to me as if it could wear away the paint once dirt and wind are involved, while the Britpart one is either open or closed, but I prefer the way it rolls up.

There is about a $20 difference in price between the two, with the Rovers North one being the less expensive.

Below: Britpart radiator muff installed.

The Rovers North radiator muff. Comes with a nicely done Rovers North label on it, too. It fits snugly over the corners of the grill, but in my case would require removing the grill to install, and the captive nuts are loose enough already.

3 Bros, kindly supplied two versions to try. The first was from Rovers North, the second from Britpart. In the end, I chose the Britpart one.

Both will do the job. The Rovers North one is of somewhat higher quality, but more difficult to install and remove, and I could see the fabric being difficult to clean if necessary. The Britpart one was very easy to install, just requiring some tie-wraps (one set of which comes with the muff, and are cheap to purchase afterwards in any case), and the vinyl surface will be easy to keep clean. The Rovers North muff provides more choices of opening sizes, but the adjustable flap folds and hangs down over and against the apron, which looked to me as if it could wear away the paint once dirt and wind are involved, while the Britpart one is either open or closed, but I prefer the way it rolls up.

There is about a $20 difference in price between the two, with the Rovers North one being the less expensive.

Below: Britpart radiator muff installed.

The Rovers North radiator muff. Comes with a nicely done Rovers North label on it, too. It fits snugly over the corners of the grill, but in my case would require removing the grill to install, and the captive nuts are loose enough already.

Sunday, November 11, 2012

Tuesday, November 6, 2012

Pottering Around

When for a customary lunch time Land Rover drive today, for a bit of fresh air and to let the vehicle stretch its legs. At one point, there were deer standing by the road, and they continued to stay there when I stopped the Landy - and so I took a photo. Not exactly African wildlife, but taking pictures of animals from Land Rovers does sort of go with the traditional image. :)

Getting colder outside, -4 C today, and I notice the coolant temp shows that the engine is only at full temperature when at higher rpm's. Ordered a radiator muff a while ago, which I understand will be here in the next few days, and it looks as if it will be useful. In the photo below, taken today, the tires and mudflaps are showing that not all driving is being done on smooth paved surfaces.... :)

Getting colder outside, -4 C today, and I notice the coolant temp shows that the engine is only at full temperature when at higher rpm's. Ordered a radiator muff a while ago, which I understand will be here in the next few days, and it looks as if it will be useful. In the photo below, taken today, the tires and mudflaps are showing that not all driving is being done on smooth paved surfaces.... :)

Wednesday, October 24, 2012

Still Autumn

Wednesday, October 17, 2012

Tow Hitch

Nothing major, but decided it was time to put on the last assembly that would bring the Land Rover back to the configuration it was in when purchased. I wanted to keep the original pin-type fitting, partly for authenticity and partly as it's useful for recovery, plus a ball mount for versatility.

provided the complete kit, which included the bolts, nuts and a generous supply of galvanized washers. The mounting and backing plates were galvanized by 3 Bros. - they don't come from the supplier this way. A very nice consideration by 3 Bros..

The only issues during assembly: the galvanizing of the chassis had made the bolt holes too small by a small fraction, and had to be drilled out. A larger problem was that the holes of the mounting plate and those of the chassis didn't line up - the top right was out of position. This had to be corrected for the bolt to go through.

Below, the kit, with tow ball masked off in preparation for priming and painting. The ball/pin casting is zinc plated.

Just a view of the casting with self-etch primer so the paint will adhere to the zinc, and after painting.

On the left, the original pin-only fitting (welded to mounting plate, in turn welded to rear cross member when the previous owners made their own replacement cross member).

The thick backing plate has to be placed in location first (to prevent pull-through of the bolts when under load), then the nuts, and then the bolts put through from the outside. There isn't room for lock washers. A check for tightness will be needed now and then. The hitch bolts will need to be longer if double nuts are to be used.

The final assembly.

provided the complete kit, which included the bolts, nuts and a generous supply of galvanized washers. The mounting and backing plates were galvanized by 3 Bros. - they don't come from the supplier this way. A very nice consideration by 3 Bros..

The only issues during assembly: the galvanizing of the chassis had made the bolt holes too small by a small fraction, and had to be drilled out. A larger problem was that the holes of the mounting plate and those of the chassis didn't line up - the top right was out of position. This had to be corrected for the bolt to go through.

Below, the kit, with tow ball masked off in preparation for priming and painting. The ball/pin casting is zinc plated.

Just a view of the casting with self-etch primer so the paint will adhere to the zinc, and after painting.

On the left, the original pin-only fitting (welded to mounting plate, in turn welded to rear cross member when the previous owners made their own replacement cross member).

The Workshop Manual illustrations (supplied by 3 Bros.) for attaching the tow assembly. While the double-nut method worked well for the smaller upper bolts, it wasn't possible for the lower, due to the flange on the rear cross member (see next photo).

The thick backing plate has to be placed in location first (to prevent pull-through of the bolts when under load), then the nuts, and then the bolts put through from the outside. There isn't room for lock washers. A check for tightness will be needed now and then. The hitch bolts will need to be longer if double nuts are to be used.

The final assembly.

Monday, October 8, 2012

Workhorses

When walking back to the Land Rover today, I noticed this tableau. Probably 50 years here between the two trucks. I wonder if either of these has a chance of still being around in another 50 years?

Thursday, October 4, 2012

Fall Colours

When for a drive at lunch today. Fall colours just coming in, and will only last a week or two at best. Always a nice time of year.

(click on the picture for full-size view)

(click on the picture for full-size view)

Tuesday, October 2, 2012

Thermostat and Housing

The Land Rover had been running too hot ever since it went back on the road after the restoration. Everything tested ok, the coolant sytem had been flushed, thermostat worked, radiator worked, brakes weren't dragging, timing was good, etc., but temps were consistently about 20C too hot. Nothing drastic, but not normal, and something I wanted to correct.

Further testing of the old thermostat showed that it could stick shut from time to time. A look at the coolant system design also appeared to show that the large Kodiak heater hoses were likely bringing a lot of coolant directly back into the engine, coolant which doesn't pass through the radiator.

At first I tried to find a new thermostat, to see if that would cure the problem, and while I eventually found one, they are obviously very hard to come by and subsequently quite expensive. This rarity might pose problems in the future. That, and the Kodiak hose question, made me look at the later thermostats used on Series 2a and Series 3 vehicles.

Those designs (there are two types) looked as if they might have some design advantages over the original, and after some more research, the late 2a/3 type looked best. It's thermostat has a 'skirt' that blocks a large part of the flow back into the engine, the rest then going through the radiator. It also has a 'cap' that, when the engine is cold, appears to stop flow to the radiator more thoroughly and direct more coolant directly back into the engine until the engine has warmed up.

The earlier thermostat, which didn't seem as effective, is a 'waxstat', with the same permanently open hole at the top as with the bellows type, which means more coolant going immediately back into the engine without passing through the radiator. The open thermostat doesn't do that much to divert flow to the radiator except lack of resistance down the radiator channel, which is offset from the main channel.

The newer housing installs without a problem onto the older type cylinder head. I installed an 82C thermostat (the other option is 74C), went for a long drive, and the engine, once at full operating temp, stayed at 82C. Right on the money. It would seem the problem is solved.

Below, the original 1960 housing. Note how the radiator return-hose empties directly back into the engine. It still does with the new housing, but the thermostat and housing design directs far more coolant to the radiator, and appears much better able to cope.

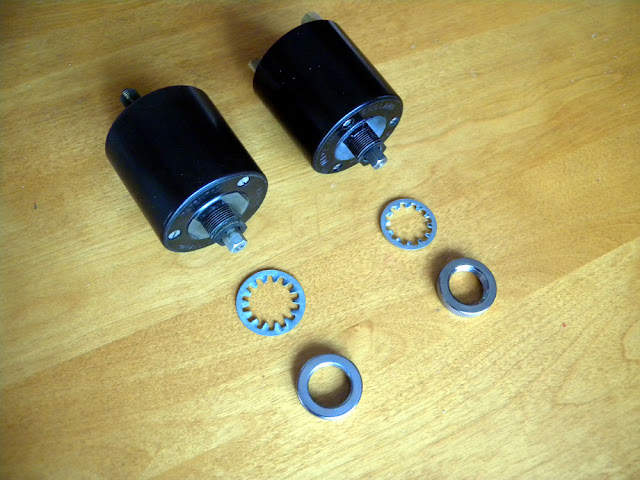

On the left, the original housing and (rare) bellows-type thermostat. On the right, the new housing with skirted thermostat and gasket in place. (Parts are sitting on spray can lids, in case you're wondering.)

On the left, the skirted thermostat and outlet housing. On the right, an earlier waxstat outlet. Note the differences in the openings. The inset image is just there to show the waxstat shape, as I don't have one here.

New housing and thermostat in place. It would seem much simpler to change thermostats with this design, too.

Have re-routed the heater return-hose to the side of the engine away from the exhaust manifold, too, in case that helps cooling by keeping the hose away from a hotter part of the engine.

Further testing of the old thermostat showed that it could stick shut from time to time. A look at the coolant system design also appeared to show that the large Kodiak heater hoses were likely bringing a lot of coolant directly back into the engine, coolant which doesn't pass through the radiator.

At first I tried to find a new thermostat, to see if that would cure the problem, and while I eventually found one, they are obviously very hard to come by and subsequently quite expensive. This rarity might pose problems in the future. That, and the Kodiak hose question, made me look at the later thermostats used on Series 2a and Series 3 vehicles.

Those designs (there are two types) looked as if they might have some design advantages over the original, and after some more research, the late 2a/3 type looked best. It's thermostat has a 'skirt' that blocks a large part of the flow back into the engine, the rest then going through the radiator. It also has a 'cap' that, when the engine is cold, appears to stop flow to the radiator more thoroughly and direct more coolant directly back into the engine until the engine has warmed up.

The earlier thermostat, which didn't seem as effective, is a 'waxstat', with the same permanently open hole at the top as with the bellows type, which means more coolant going immediately back into the engine without passing through the radiator. The open thermostat doesn't do that much to divert flow to the radiator except lack of resistance down the radiator channel, which is offset from the main channel.

The newer housing installs without a problem onto the older type cylinder head. I installed an 82C thermostat (the other option is 74C), went for a long drive, and the engine, once at full operating temp, stayed at 82C. Right on the money. It would seem the problem is solved.

Below, the original 1960 housing. Note how the radiator return-hose empties directly back into the engine. It still does with the new housing, but the thermostat and housing design directs far more coolant to the radiator, and appears much better able to cope.

On the left, the original housing and (rare) bellows-type thermostat. On the right, the new housing with skirted thermostat and gasket in place. (Parts are sitting on spray can lids, in case you're wondering.)

On the left, the skirted thermostat and outlet housing. On the right, an earlier waxstat outlet. Note the differences in the openings. The inset image is just there to show the waxstat shape, as I don't have one here.

New housing and thermostat in place. It would seem much simpler to change thermostats with this design, too.

Have re-routed the heater return-hose to the side of the engine away from the exhaust manifold, too, in case that helps cooling by keeping the hose away from a hotter part of the engine.

Just needing the fan shroud to go back on, once another test drive confirms there are no leaks.

Finally, after a long test drive, fan shroud re-installed, and heater hose attached to center bolt of the valve cover with an aviaton hose clamp, to stop the hose touching the ignition wire or valve cover.

Tuesday, September 18, 2012

'Eyebrow' Headliners

Finally got around to doing the 'eyebrow' headliners. These are steel stamped plates covered with glued-on fabric-backed vinyl. The steel had become heavily surface-rusted and this had pushed off and to some degree distorted the vinyl surface. The glue itself hadn't survived particularly well, either. The vinyl came off just by pulling up the fold-over sections. The vinyl itself had survived pretty well for it's age, however, although the small bumps from the rust, and other distortions formed around screw holes and places where the headliner touched the body, were impossible to get rid of. The fold-around edge locations were definitely there to stay, but this helped to put the vinyl back on exactly as it was originally.

Below, the basic steel forms, de-rusted and painted with a rust-paint.

Finally painted the halves with the excellent paint for vinyl used for the roof headliner.

Just an after and before view. Note how screw holes and top edges do not lign up. Welcome to quality control, 1960-style.

All three original headliners, roof and eyebrow, installed with their original vinyl. Very happy to have been able to keep them.

The vinyl glued back on, using 3M's High-Tack Spray Adhesive. The vinyl insisted on keeping most of it's original shape, and to counter this the internal edges were taped down after painting to prevent slow curling and hopefully eliminate future delamination. The cut of the vinyl is factory original; that's how it looked originally. Not pretty, but it did the job.

Test fit of both headliner halves. That is not their original colour - they were white, as was clearly shown by the areas that had remained hidden. That's just 50 years of dirt, possibly combined with cigarette smoke, who knows.

Finally painted the halves with the excellent paint for vinyl used for the roof headliner.

Just an after and before view. Note how screw holes and top edges do not lign up. Welcome to quality control, 1960-style.

All three original headliners, roof and eyebrow, installed with their original vinyl. Very happy to have been able to keep them.

Friday, September 7, 2012

Door Seal Rivets

The by-the-foot rubber door seals that were installed have been peeling off, in spite of using very good quality 3M glue. I spoke to Peter Baker at 3 Bros.and he kindly sent over a complete kit of new door seals for the Land Rover, the purpose-made ones with metal strip inserts, the kit including the correct tubular rivets and the loan of a top-of-the-line river squeezer. A really nice quality kit.

Unfortunately the peculiarities of this vehicle (factory body assembly left a lot to be desired, but was kept as it's authentic to this vehicle) meant that these new seals can't really be used, as the doors will not close. Instead, after some experimentation and testing, there appears to be a way to use the tubular rivets on the by-the-foot rubber door seals. This method works well, and keeps the authentic look inside the cab.

Below: finished results, from inside the cab, at rear of door. No more holes, just nice new aluminum rivet heads.

In the plastic bag, the rivets as supplied by 3 Brothers Classic Rovers. A box of 3/16" aluminum backing plates were purchased elsewhere, to serve as the metal support plates inside the rubber door seal.

Secondly, use a pair of needle-nose pliars to slide a backing plate into the hole. The rubber is quite stretchy, and will allow the backing plate in and then essentially close up afterwards.

That's all! : )

Below: finished results, from inside the cab, at rear of door. No more holes, just nice new aluminum rivet heads.

In the plastic bag, the rivets as supplied by 3 Brothers Classic Rovers. A box of 3/16" aluminum backing plates were purchased elsewhere, to serve as the metal support plates inside the rubber door seal.

First step, drill a 3/16" hole into the rubber seal from the inside surface, going only through the first two layers (out of three). Don't drill through the outer curved part. Keep the drill turning quickly so that the rubber doesn't bind to the bit.

Secondly, use a pair of needle-nose pliars to slide a backing plate into the hole. The rubber is quite stretchy, and will allow the backing plate in and then essentially close up afterwards.

Third step, center the backing plate within the seal using an awl or whatever serves the purpose. The rubber will keep the backing plate in position once it's where it needs to be.

The next step is done on the Land Rover - just doing it here for illustration. Push the rivet through the hole in the door seal flange on the Land Rover, then through the seal and backing plate. Then the tubular rivet can be squeezed very easily. The rivet squeezer means the pressure on the river can be modulated to be just tight enough to hold the seal, without flattening the inner surface of the seal too much and thus distorting the seal, as usually happens with pop rivets.

That's all! : )

Wednesday, September 5, 2012

Long Short Drive.

On a nice day between two rainy ones, took the dog for a short drive after work. If you've twelve minutes to spare, or want to see what it's like driving a Land Rover, or are just having trouble falling asleep, come along for the drive. : )

Monday, September 3, 2012

Self Cancelling Vacuum Indicator Switch

Installed the new indicator switch today. The original still worked, but the vacuum element was broken, and so had to be turned off manually. This meant that, often enough, I'd forget to turn it off as the switch is not readily in view. The new switch was ordererd from Holden UK, here, and arrived quickly and was well packed. Quite a pricey unit, but as they are difficult to find and a working switch was needed, so be it.

I thought it would be just a matter of a few minutes to install, but the old Land Rover motto (at least for me) "what you think will be easy will in fact be difficult, and vice versa" came into play.

First, though, the new part is almost identical in appearance to the original. The original has the name Lucas on the back, the new simply has the made in UK info, but the body is the same bakelite-type material. The differences:

- The original had a galvanized large lock washer, the new appears to be simply plated.

- The screw-on ring of the new is not of the same quality as the original, but the original can be used on the new switch (as with the original lock washer).

- The openings on the lock-screws on the rear face inwards, whereas on the original they face outwards.

The problem area: the new unit didn't fit through the original hole in the auxiliary panel. And so the wires had to be undone again, and a file used to take off the required amount (approx 1mm from each 'flat' side of the threaded mount) from the switch body. The bakelite is somewhat fragile, and the filing caused some chipping, but only a very small amount. The filing also curled material into the threads, and so they had to be cleaned afterwards. Not a big problem overall, but still unexpected.

The new unit works perfectly, and it's nice to see the turn signals go off automatically. The only other area of potential concern is that it now takes a lot more effort to turn the signal switch lever itself, and I'm a bit worried the old plastic lever will not take the strain for too long. However, that remains to be seen, and new switch levers are available - but not in the original white, unfortunately.

Below, the original on the left, the new on the right.

I thought it would be just a matter of a few minutes to install, but the old Land Rover motto (at least for me) "what you think will be easy will in fact be difficult, and vice versa" came into play.

First, though, the new part is almost identical in appearance to the original. The original has the name Lucas on the back, the new simply has the made in UK info, but the body is the same bakelite-type material. The differences:

- The original had a galvanized large lock washer, the new appears to be simply plated.

- The screw-on ring of the new is not of the same quality as the original, but the original can be used on the new switch (as with the original lock washer).

- The openings on the lock-screws on the rear face inwards, whereas on the original they face outwards.

The problem area: the new unit didn't fit through the original hole in the auxiliary panel. And so the wires had to be undone again, and a file used to take off the required amount (approx 1mm from each 'flat' side of the threaded mount) from the switch body. The bakelite is somewhat fragile, and the filing caused some chipping, but only a very small amount. The filing also curled material into the threads, and so they had to be cleaned afterwards. Not a big problem overall, but still unexpected.

The new unit works perfectly, and it's nice to see the turn signals go off automatically. The only other area of potential concern is that it now takes a lot more effort to turn the signal switch lever itself, and I'm a bit worried the old plastic lever will not take the strain for too long. However, that remains to be seen, and new switch levers are available - but not in the original white, unfortunately.

Below, the original on the left, the new on the right.

Thursday, August 30, 2012

Night Drive

It occurred to me that the Land Rover hasn't been driven at night since the basic restoration was completed. And so, this evening, took the Land Rover out in the dark, along country roads and then a second drive a while later, up the faster main road for a mile or two.

Nice to dicover that the headlights are really good, and do an excellent job, both in low and high beam. Instrument panel lights do their job equally well. A very enjoyable set of evening drives - the only worry being deer crossing the roads on the dark stretches.

Since it's first test drive on January 9 this year, the Land Rover has now done 727 kilometers. Most of those kilometers have been done since April.

Nice to dicover that the headlights are really good, and do an excellent job, both in low and high beam. Instrument panel lights do their job equally well. A very enjoyable set of evening drives - the only worry being deer crossing the roads on the dark stretches.

Since it's first test drive on January 9 this year, the Land Rover has now done 727 kilometers. Most of those kilometers have been done since April.

Sunday, August 26, 2012

Carter's Birthday

Carter being the son of Steve and Nicole. Steve being the technician/mechanic/restorer who came down last winter to ensure that I had done a good job restoring the Land Rover. The Land Rover being what took us up to Steve and Nicole's today for Carter's birthday party.

Below, about ready to go, GPS on the windshield (it's my km/h speedometer), car seat for my daughter installed, and a yellow sticky with directions. Yellow sticky plus a GPS? Yup, the yellow sticky us easier to read at a glance in the bright light outdoors.

An hour's drive later, parked at Steve's, between a Mini and Jim's Jag. A hot drive up, as even with the window vents and windows open, a lot of heat is transferred into the cabin. This not helped by having the Kodiak heater on, as it helps to bring the coolant temp down in the hot humid conditions. Although it's possible to direct the Kodiak's outflow, enough hot air escapes around the baffles in the box to keep your feet warm. Nice in cold temperatures!

Just a further view, with a Porche 911 under wraps. Yes, Steve does those, too. Steve's old workshop in the foreground, and new top-of-the-line facility in the background.

The gathering. Why there is a yellow car jack stand in the middle of the lawn, I do not know, but I'm sure there's a good reason. Thank you, Nicole and Steve, for a very enjoyable afternoon.

Getting ready to come home. Actually a very comfortable vehicle to ride in. A bit slow on faster roads, but then, I just pull over to let the traffic go by and it's not a problem. Aside from being a little warm inside, and being a little slow at times, it really is nice vehicle to drive. Next summer, however, it may be nice to take the roof off, or even perhaps try a canvas roof that can have the sides rolled up.

Below, about ready to go, GPS on the windshield (it's my km/h speedometer), car seat for my daughter installed, and a yellow sticky with directions. Yellow sticky plus a GPS? Yup, the yellow sticky us easier to read at a glance in the bright light outdoors.

An hour's drive later, parked at Steve's, between a Mini and Jim's Jag. A hot drive up, as even with the window vents and windows open, a lot of heat is transferred into the cabin. This not helped by having the Kodiak heater on, as it helps to bring the coolant temp down in the hot humid conditions. Although it's possible to direct the Kodiak's outflow, enough hot air escapes around the baffles in the box to keep your feet warm. Nice in cold temperatures!

Just a further view, with a Porche 911 under wraps. Yes, Steve does those, too. Steve's old workshop in the foreground, and new top-of-the-line facility in the background.

The gathering. Why there is a yellow car jack stand in the middle of the lawn, I do not know, but I'm sure there's a good reason. Thank you, Nicole and Steve, for a very enjoyable afternoon.

Getting ready to come home. Actually a very comfortable vehicle to ride in. A bit slow on faster roads, but then, I just pull over to let the traffic go by and it's not a problem. Aside from being a little warm inside, and being a little slow at times, it really is nice vehicle to drive. Next summer, however, it may be nice to take the roof off, or even perhaps try a canvas roof that can have the sides rolled up.

Subscribe to:

Posts (Atom)