Opened up the turn indicator, partly to clean and partly to see how it works. I have read somewhere that it may be of the self-cancelling type, but although I don't quite understand the design, I can't see the spring in there being strong enough to do anything. The contact mover that moves with the handle to turn the indicators on and off is quite stiff, and I can't see the spring overcoming that, even when new. However, there is definitely something more to the design, what with the cam and adjuster screw on the backsideof the housing. Anyway, everything was cleaned and lubricated, and as a manual on/off type switch it should work well.

Will clean the panel itself closer to re-installment time. The green plastic outer lens of the turn indicator light is fractured, but I'm hoping glue and some polishing will help. The yellow pull on/off switch, for the dome light, has "Made in the USA" stamped on the inner box, and so I don't think it's a factory option; more likely installed by the dealer in Toronto. Also, the hole in the panel isn't as neat as that for the turn indicator and light.

This is just a simple pictorial history of my restoration of an original Canadian-import 1960 Land Rover Series 2 88" (or SWB - Short Wheel Base), LHD (Left Hand Drive) which I purchased in August, 2010. Later posts include photos of some of the things I've done with the vehicle since its restoration was essentially completed, although repairs and other maintenance are obviously an ongoing process. Words in orange are links. Click the photos to make them full size. Search using box below.

Search This Blog

Tuesday, March 29, 2011

Friday, March 25, 2011

Bulkhead Off; Exhaust Manifold

Took surprizingly little time and no trouble to get the bulkhead off, using the engine hoist. I don't know why I expected it to be more complicated! And of course, once it was off, all that new dirt and grime was revealed, but that's to be expected. Lots of part cleaning and painting coming up!

Overview of the project area. It now feels as if there's a lot more room. That feeling, however, I think will disappear when the new bulkhead arrives.

Two view of the engine and gearbox, with something like 51 years of grime attached. The wiring harness, being fabric covered, has absorbed a lot of oil and dirt and is rotting everywhere. The new harness should take care of that.

Never thought I'd have two Land Rover chassis' in the garage. : )

An unusual view of a Land Rover?

The exhaust manifold had two very hard to remove bolts, due to being rusted solid and in difficult to reach places, but perserverance, a drill and a cold chisel eventually won out. At top, the intake manifold; centre, the new exhaust manifold; at bottom, the goose-neck exhaust manifold. I think I may paint the new manifold, as that shiny silver is a bit much.

Can't quite understand the use of what must have been a cable operated valve in the manifold. It has a spring, and so I gather use was temporary, but why would one want to cut off exhaust flow?

EDIT: This from 'athorpe' of the S2C Club: "It was to direct the exhaust to the base of the inlet manifold to heat it, when the engine is warm it diverts it down the exhaust pipe, so its only restricted when cold. The spring is a bi-metalic one, so does the above when hot and cold ." Voila.

Overview of the project area. It now feels as if there's a lot more room. That feeling, however, I think will disappear when the new bulkhead arrives.

Two view of the engine and gearbox, with something like 51 years of grime attached. The wiring harness, being fabric covered, has absorbed a lot of oil and dirt and is rotting everywhere. The new harness should take care of that.

Never thought I'd have two Land Rover chassis' in the garage. : )

An unusual view of a Land Rover?

The exhaust manifold had two very hard to remove bolts, due to being rusted solid and in difficult to reach places, but perserverance, a drill and a cold chisel eventually won out. At top, the intake manifold; centre, the new exhaust manifold; at bottom, the goose-neck exhaust manifold. I think I may paint the new manifold, as that shiny silver is a bit much.

Can't quite understand the use of what must have been a cable operated valve in the manifold. It has a spring, and so I gather use was temporary, but why would one want to cut off exhaust flow?

EDIT: This from 'athorpe' of the S2C Club: "It was to direct the exhaust to the base of the inlet manifold to heat it, when the engine is warm it diverts it down the exhaust pipe, so its only restricted when cold. The spring is a bi-metalic one, so does the above when hot and cold ." Voila.

Wednesday, March 23, 2011

Bulkhead Ready to Come Off.

Finished stripping the old bulkhead tonight, and it's now being held in place just by the two main bolts (nuts are off), and is leaning against the one remaining support bracket. It will be off soon.

Just a few of the things liberated from behind the instrument panels. Nothing of value unfortunately!

How many holes are there in a bulkhead? Well, once everything is off, it turns out there are quite a few. Apologies for the blurry photo, but is was dark.

After 51 years of service, the old nut locking plates on the swivel hub control arms were finally replaced with the new ones, and that's that done.

A view of the front end, about to receive the brakes; then the hubs will be installed along with the drums.

Just a few of the things liberated from behind the instrument panels. Nothing of value unfortunately!

How many holes are there in a bulkhead? Well, once everything is off, it turns out there are quite a few. Apologies for the blurry photo, but is was dark.

After 51 years of service, the old nut locking plates on the swivel hub control arms were finally replaced with the new ones, and that's that done.

Monday, March 21, 2011

Stripping Old Bulkhead Continues

Continued taking items off of the old bulkhead this evening, tonight being the turn of the steering column and box, along with the accelerator pedal and linkages.

A couple of views of the round junction box:

An overall view of things as they stand now. Remains of the old electrical loom may stay until the new bulkhead is installed and wired up, as the new loom that will be installed does not have the wires for the turn signals, and I'll need to know how to hook them up.

Engine looking a little more exposed. At lower left is what I believe is the original single pulley for the generator, which was removed so that a double could also power the hydraulic snowplow arm. It was wedged between the bulkhead and chassis, at lower right. Tried to get the exhaust and inlet manifolds off tonight, but each has one very seized/rust corroded bolt in a very awkward spot that will take some thought. Note the gooseneck exhaust manifold, which will be replaced with a standard later version, as it goes straight down and will match up with the new exhaust pipes. Would like to get the engine off soon.

A quick view of the auxiliary panel and the hand throttle. I have a replacement starter button, so I hope the original doesn't turn up somewhere! The two rusty items protruding downwards are actually large nails trapped in the bulkhead. Wouldn't want to have swung a foot or knee up onto those. They'll come out when the bullets come out. The black goop on the bulkhead is the adhesive for the insulation that used to be there.

A couple of views of the round junction box:

An overall view of things as they stand now. Remains of the old electrical loom may stay until the new bulkhead is installed and wired up, as the new loom that will be installed does not have the wires for the turn signals, and I'll need to know how to hook them up.

Engine looking a little more exposed. At lower left is what I believe is the original single pulley for the generator, which was removed so that a double could also power the hydraulic snowplow arm. It was wedged between the bulkhead and chassis, at lower right. Tried to get the exhaust and inlet manifolds off tonight, but each has one very seized/rust corroded bolt in a very awkward spot that will take some thought. Note the gooseneck exhaust manifold, which will be replaced with a standard later version, as it goes straight down and will match up with the new exhaust pipes. Would like to get the engine off soon.

A quick view of the auxiliary panel and the hand throttle. I have a replacement starter button, so I hope the original doesn't turn up somewhere! The two rusty items protruding downwards are actually large nails trapped in the bulkhead. Wouldn't want to have swung a foot or knee up onto those. They'll come out when the bullets come out. The black goop on the bulkhead is the adhesive for the insulation that used to be there.

Sunday, March 20, 2011

Steering Parts; Instruments

Thanks to a tip from a gentleman and fellow Series 2 restorer named Lars, the top steering arm bolt on the steering relay has now been reversed - as Lars discovered, in this direction it's easier to remove the bolt in the direction of the 'breakfast', if necessary. No radiator in the way. On RHD cars the bolts is the way it was originally (and would have drawn out towards the front), but when making a LHD vehicle, the factory just turned the unit around as they moved the relay from one side of the chassis to the other.

As the new bulkhead is getting closer, tonight it was the turn of some of the steering coumn parts to come off the old bulkhead for their turn at restoration. Note the condition of the rubber seal for the steering column - the exposed portion hasn't stood the test of time too well! A nice new replacement is waiting....

The steering column itself, including the steering box, is next on the list. All the bolts are loosened, but ran out of time tonight.

Just a couple more views of the rear of the main instrument panel. Nice untouched Pastel Green paint back there, as well.

As the new bulkhead is getting closer, tonight it was the turn of some of the steering coumn parts to come off the old bulkhead for their turn at restoration. Note the condition of the rubber seal for the steering column - the exposed portion hasn't stood the test of time too well! A nice new replacement is waiting....

The steering column itself, including the steering box, is next on the list. All the bolts are loosened, but ran out of time tonight.

Just a couple more views of the rear of the main instrument panel. Nice untouched Pastel Green paint back there, as well.

Saturday, March 19, 2011

Test Fitting Steering Rods

Having the swivels basically finished, just thought I'd try out the steering rods for size, to make sure everything still fits without a problem. All's well, but one of the ball joints/rod ends spun in its socket when trying to tighten the nut, maing it impossible, and so it looks as is they may need replacing. Also, the dimensions I have for the rod lengths doesn't appear accurate at first glance, as putting the rod ends at the indicated distance apart gave a pronounced toe-in. Could it be a Series 2 versus Series 2a thing? Will have to check on this.

View below shows the completed swivel housings, with the interior of the brake backing plates painted in that stainless-steel based brake fluid resistant paint. Not completely sure it's necessary, but thought I'd try it out. Certainly has a nice finish. The locking plates were slightly too long, so are bowed in the middle, but that's not really an issue. The tabs will be folded around the nuts once I'm confident all's well and the nuts will not need any further tightening.

Here's a view of the steering relay, once again installed. Note the different surface textures on the chassis, some due to the nature of the surface of a particular piece of metal used to make the chassis (such as the cross member the steering relay is on), but mostly due to the galvanizing, which left little lumps and surface irregularites over most of the surfaces.

View below shows the completed swivel housings, with the interior of the brake backing plates painted in that stainless-steel based brake fluid resistant paint. Not completely sure it's necessary, but thought I'd try it out. Certainly has a nice finish. The locking plates were slightly too long, so are bowed in the middle, but that's not really an issue. The tabs will be folded around the nuts once I'm confident all's well and the nuts will not need any further tightening.

Here's a view of the steering relay, once again installed. Note the different surface textures on the chassis, some due to the nature of the surface of a particular piece of metal used to make the chassis (such as the cross member the steering relay is on), but mostly due to the galvanizing, which left little lumps and surface irregularites over most of the surfaces.

Thursday, March 17, 2011

Swivel Balls; Instruments

Finally have the swivel balls installed, but ran out of time to do the rest of the hubs. Will get to that soon. It'll be nice to have the front axles done, as it will mean a rolling chassis isn't too far away.

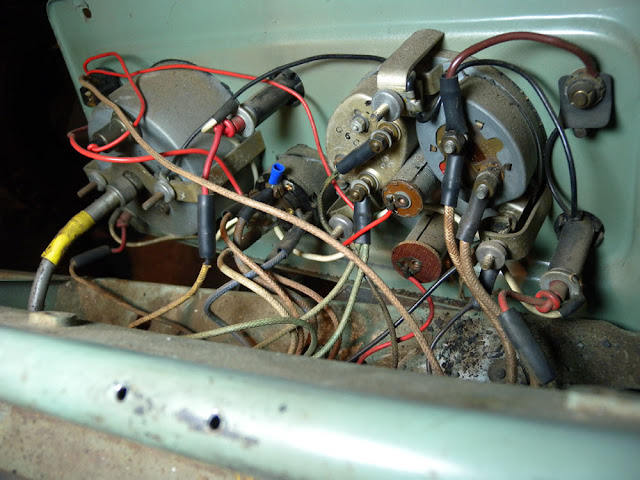

Have pulled away the instrument panels, preparatory to taking them out - but first I will take many more photos to aid re-installing. Here, the somewhat chaotic wiring of the main instrument cluster.

This view is of the turn signal and dome light auxiliary panel. At left is the switch housing, in the middle is the indicator light, and at right is the pull-knob switch for the dome light. Judging by the condition of the terminals, I doubt a dome light has ever been connected.

Here's the auxiliary panel for the oil pressure and water temperature gauge, which can't be removed unless it's unbolted from the bulkhead plus has the input leads disconnected - which I'll do later. And what is that extra thing with a light bulb at the end?

Here's a view of the bottom of the oil instrument auxiliay panel. In there was the red knob for the high/low ratio lever (had already bought a replacement, of course!), plus an assortment of bolts and debris plus a good many bullets and casings. Will be removing those with great care.

Have pulled away the instrument panels, preparatory to taking them out - but first I will take many more photos to aid re-installing. Here, the somewhat chaotic wiring of the main instrument cluster.

This view is of the turn signal and dome light auxiliary panel. At left is the switch housing, in the middle is the indicator light, and at right is the pull-knob switch for the dome light. Judging by the condition of the terminals, I doubt a dome light has ever been connected.

Here's the auxiliary panel for the oil pressure and water temperature gauge, which can't be removed unless it's unbolted from the bulkhead plus has the input leads disconnected - which I'll do later. And what is that extra thing with a light bulb at the end?

Here's a view of the bottom of the oil instrument auxiliay panel. In there was the red knob for the high/low ratio lever (had already bought a replacement, of course!), plus an assortment of bolts and debris plus a good many bullets and casings. Will be removing those with great care.

Thursday, March 10, 2011

Pedals Out

To do something a little different today, the clutch and brake pedals were removed, along with the "bean can" brake fluid reservoir. This also afforded a little better view of the rust around this area. Interesting to compare the pedal openings with those on the new galvanized chassis. Aside from the bulkhead, though, everything else is in pretty good shape aside from surface rust and dirt.

Not too much left here! The accelerator pedal will come one next, but only after I carefully photograph all the linkages, etc.. The black substance on the bulkhead is the remains of the glue that held on the original insulation. The strait-edged sheet metal at bottom is just something the previous owner had put to stop his feet going all the way through....

Not too much left here! The accelerator pedal will come one next, but only after I carefully photograph all the linkages, etc.. The black substance on the bulkhead is the remains of the glue that held on the original insulation. The strait-edged sheet metal at bottom is just something the previous owner had put to stop his feet going all the way through....

Wednesday, March 9, 2011

Axle Work

With the differentials complete, they've been attached to their respective axle casings, and the casings are now attached to the springs. The rear axle just needs its hubs and brakes, while work should begin soon reassembling the swivel hubs at the front.

In this view, it's just about possible to note that the insides of the brake backing plate has been painted with Eastwood's brake fluid-resistant paint, which is stainless steel based (and silver in colour).

In this view, it's just about possible to note that the insides of the brake backing plate has been painted with Eastwood's brake fluid-resistant paint, which is stainless steel based (and silver in colour).

Ready for the swivel hubs:

Monday, March 7, 2011

New Galvanized Bulkhead

Ashtree Landrover International were kind enough to send two photos of the new bulkhead as it was being prepared for crating and shipping, and so I thought I'd share the pictures. Bulkhead looks really good, and note the 'extras' in the 'glove shelf' - these will be very welcome!

Friday, March 4, 2011

Hand Brake Re-assembled

Put the hand brake together this afternoon. Hopeful that it works (and looks) a little better than when it was taken off! The outer backing plate shows some signs of its former surface rust under the paint, but the inside was almost rust free. New parts are the brake pads and springs, plus the locking plate, packing plate, retaining spring and their rubber dust cover (which were completely missing). The rest is original.

Wednesday, March 2, 2011

Tires Removed from Rims

Today's lunch time project was to get the tires off, which was done by the good folks at the local Firestone tire center. Let the air out of all five tires before taking them over, and boy did the air inside small bad! However, once the tires were off, nice to see that the wheels are in good overall shape. The paint inside almost appears to have been painted by a brush, or is that due to the tubes? In the next couple of weeks they should be off to a specialist for soda-blasting, and then I'll be painting them back to their original Limestone off-white colour (as per the top-most rim seen here).

The second is the wheel part number, described in my Land Rover Parts Catalogue as "Road wheel, well base rim type."

Two views of numbers stamped on the wheels: the first is the year of manufacture, I assume.

The second is the wheel part number, described in my Land Rover Parts Catalogue as "Road wheel, well base rim type."

Subscribe to:

Posts (Atom)