Installed the new indicator switch today. The original still worked, but the vacuum element was broken, and so had to be turned off manually. This meant that, often enough, I'd forget to turn it off as the switch is not readily in view. The new switch was ordererd from Holden UK,

here, and arrived quickly and was well packed. Quite a pricey unit, but as they are difficult to find and a working switch was needed, so be it.

I thought it would be just a matter of a few minutes to install, but the old Land Rover motto (at least for me) "what you think will be easy will in fact be difficult, and vice versa" came into play.

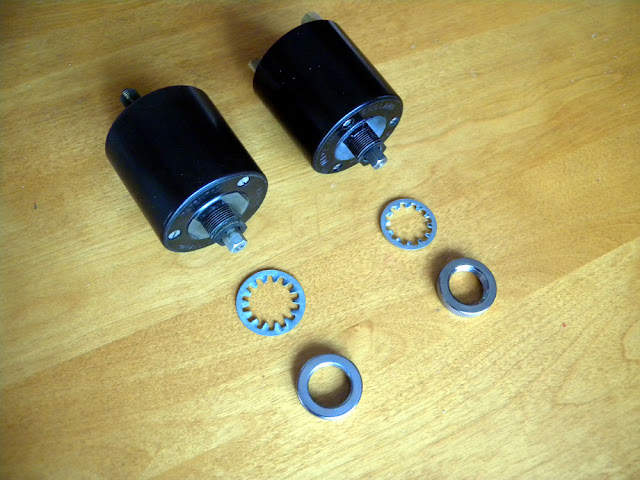

First, though, the new part is almost identical in appearance to the original. The original has the name Lucas on the back, the new simply has the made in UK info, but the body is the same bakelite-type material. The differences:

- The original had a galvanized large lock washer, the new appears to be simply plated.

- The screw-on ring of the new is not of the same quality as the original, but the original can be used on the new switch (as with the original lock washer).

- The openings on the lock-screws on the rear face inwards, whereas on the original they face outwards.

The problem area: the new unit didn't fit through the original hole in the auxiliary panel. And so the wires had to be undone again, and a file used to take off the required amount (approx 1mm from each 'flat' side of the threaded mount) from the switch body. The bakelite is somewhat fragile, and the filing caused some chipping, but only a very small amount. The filing also curled material into the threads, and so they had to be cleaned afterwards. Not a big problem overall, but still unexpected.

The new unit works perfectly, and it's nice to see the turn signals go off automatically. The only other area of potential concern is that it now takes a lot more effort to turn the signal switch lever itself, and I'm a bit worried the old plastic lever will not take the strain for too long. However, that remains to be seen, and new switch levers are available - but not in the original white, unfortunately.

Below, the original on the left, the new on the right.