The doors are on, as are the sill panels on one side. I thought it would be pretty straight forward, just bolting things together, but noooo, it's taken a few hours of adjustment and then readjustment. There's a reason so many bolt holes on a Land Rover are oblong and not round.

Here, a view to shock the purists, perhaps! The Land Rover with her wrinkled rear panel, a souvenir from work-related activities some time in the 1960's, but also showing the doors installed plus one of the ABS plastic front outer panels, from Paddock's, that was installed to ensure everything lined up as it should. Original aluminum panels just weren't available, unfortunately. The rear vertical cappings are being held in place with clico's for the time being, but the riveting should be done soon.

The passenger-side door, showing a couple of its own small dents. Getting everything including the sill panels to fit evenly was a real challenge and took a lot of time.

Just a view of the weatherstipping, and the 3M weatherstripping glue used for attachment. The weatherstripping will also be riveted, later on.

The lower weatherstripping. I had installed the official Land Rover weatherstipping here, but it was far too robust and the door simply wouldn't close properly, even with the sill rail moved all the way in. And so, off it came, and this substituted. This segment is riveted on. The door now fits just perfectly.

A view of the passenger side door. The metal handle is a replacement from Blanchard's, as the original had been lost, otherwise everything is original. The plastic on the door handles had come off, and so they were re-dipped with three coats of Plasti-Dip. The forward door seal will be attached once the windscreen is on, so that the seal can be sure to meet up with the one on the windscreen frame.

The driver's side door. Everything here is original to this Land Rover, including the pull handle, with the exception of the outer door handle, which also needed new coats of Plasti-Dip.

This is just a simple pictorial history of my restoration of an original Canadian-import 1960 Land Rover Series 2 88" (or SWB - Short Wheel Base), LHD (Left Hand Drive) which I purchased in August, 2010. Later posts include photos of some of the things I've done with the vehicle since its restoration was essentially completed, although repairs and other maintenance are obviously an ongoing process. Words in orange are links. Click the photos to make them full size. Search using box below.

Search This Blog

Wednesday, September 28, 2011

Sunday, September 25, 2011

Tub Exterior Painted

Another area of the gold colour applied by the previous owner some 35 years ago has disappeared. Today the tub returned completely to its colour of origin for the first time in more than three decades, with the sanding down, masking off and then painting of the exterior sides. Now just have to be patient for a few days and then the doors and sill panels can go on - although the door seals may have to go on first.

Here, the doors are in the tub to stay out of the way, and continue their own drying process. Note the backs of the Exmoor Trim seats, which are pretty ugly and un-finished looking compared to the originals. May have to see if I can do something there. Planks on the garage floor remind my feet not to come too close to drying paint.

Not the best lighting, as I was just on my way out, but she certainly seems to be coming along. Angle grinder is on the bumper as there is a small bit of metal that must come off the bulkhead where it meets the floor on the driver's side, as it's impeding the placing of the final spire nut: tomorrow's job.

Here, the doors are in the tub to stay out of the way, and continue their own drying process. Note the backs of the Exmoor Trim seats, which are pretty ugly and un-finished looking compared to the originals. May have to see if I can do something there. Planks on the garage floor remind my feet not to come too close to drying paint.

Not the best lighting, as I was just on my way out, but she certainly seems to be coming along. Angle grinder is on the bumper as there is a small bit of metal that must come off the bulkhead where it meets the floor on the driver's side, as it's impeding the placing of the final spire nut: tomorrow's job.

Saturday, September 24, 2011

Seats

After some trial and error, have the seats installed: fun to sit in the Land Rover again! Seats are by Exmoor Trim, supplied by Rovers North.

I found the wooden strips on the bottoms to be too narrow to keep the seats in place, and the first time I sat on one of the seats it came off the rails, with the staples that hold the fabric on making some good scratches in the rail paint. Not very pleased with that. Solution I came up with was to purchase some wooden strips myself, cut them to fit, then glue and screw them to the seat bottoms. Had the whole family in the vehicle afterwards, wriggling around, and the seats now stayed in place.

The seats: firm but comfortable. Of course, in a stationary vehicle is not the best place to judge, but at least for now they're quite nice. I have the rubber bumpers and leather straps for them, but as usual, there are no instructions, and so it'll take some guess work. Seat construction is completely unlike the originals.

The new strips, carefully measured, glued and screwed into place.

Original seat bottoms and backs. How did the bottoms stay on the rails? Just with the leather straps at the forward end (of which there is just the one remaining, bottom right)?

The interior is slowly coming together, with various items being fitted and tested. The lever knobs are all original.

My daughter, Land Rover dreaming.... : ) Note also a test fit of a vent seal.

Did I mention the door exteriors are now painted, as well? : )

I found the wooden strips on the bottoms to be too narrow to keep the seats in place, and the first time I sat on one of the seats it came off the rails, with the staples that hold the fabric on making some good scratches in the rail paint. Not very pleased with that. Solution I came up with was to purchase some wooden strips myself, cut them to fit, then glue and screw them to the seat bottoms. Had the whole family in the vehicle afterwards, wriggling around, and the seats now stayed in place.

The seats: firm but comfortable. Of course, in a stationary vehicle is not the best place to judge, but at least for now they're quite nice. I have the rubber bumpers and leather straps for them, but as usual, there are no instructions, and so it'll take some guess work. Seat construction is completely unlike the originals.

The new strips, carefully measured, glued and screwed into place.

Looking back: the original seats. May still get these re-uphostered one day, as their basic frames and springs are in excellent shape.

Original seat bottoms and backs. How did the bottoms stay on the rails? Just with the leather straps at the forward end (of which there is just the one remaining, bottom right)?

The interior is slowly coming together, with various items being fitted and tested. The lever knobs are all original.

My daughter, Land Rover dreaming.... : ) Note also a test fit of a vent seal.

Did I mention the door exteriors are now painted, as well? : )

Monday, September 19, 2011

Automec Brake Line Kit (Part 2)

(Part 1 is here)

(Part 1 update is here)

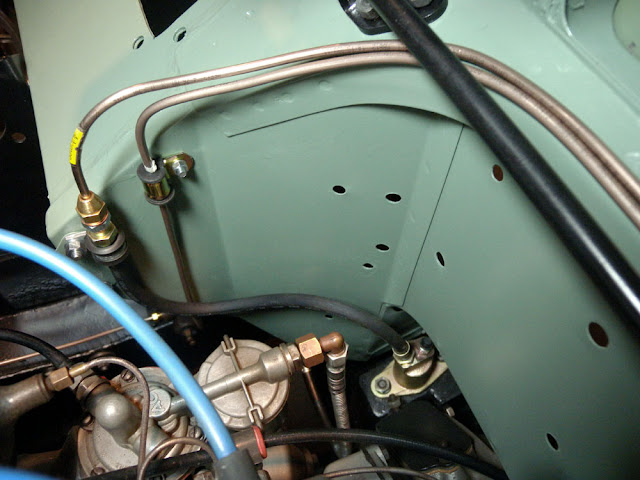

Finally installed the last of the Automec brake and clutch lines. As with the chassis and axle lines, it's a bit hard to know exactly what to do, but thankfully my Land Rover was a relatively un-messed with example (meaning everything was thankfully more-or-less as it was when it left the factory), and it was more-or-less possible to see what might have been original line routing and what was just an ad-hoc repair job later.

As well, Peter at 3 Brothers Classic Rovers very kindly took some photos of the pedal box areas in some of his LHD Land Rovers, which enabled some cross referencing.

I don't know if the end result is accurate or not, but it does follow most of the available evidence I could find, and just tried to be logical and safe when in doubt. The brake pipe, as it exits the m/c, could have curved over and gone below the steering shaft (as it does on the clutch m/c), but it would have meant a very tight bend, plus I don't have a wheel that small on my bending tool! The only part that is definitely not standard is the aircraft rubber-cushioned clamp used to hold the clutch slave hose to the bukhead - it was just the right size, and a very high quality part, and does the job perfectly. Also routed the pipes along the curved edge of that part of the bulkhead, to give maximum access to the area behind the engine and things like the flywheel opening.

Not knowing how the pipe lengths would work out, the clutch line was done first, starting from the clutch master cylinder and working towards the rubber hose connection (as there's more flexibility with dimensions at that end), and then the brake line was done starting from the 5-way connection and ending at the brake master cylinder (as I estimated the most excess length would come in useful there).

The two lines are also clamped to the bulkhead at two places between the master cylinders and the clamps visible here. The direction of the brake line clamp, seen on the right, here, was reversed from the original as it was somewhat of an awkward fit as it overlapped the bend in the bulkhead; it also enabled a slightly more direct entry into the 5-way connector (just visible below).

(Part 1 update is here)

Finally installed the last of the Automec brake and clutch lines. As with the chassis and axle lines, it's a bit hard to know exactly what to do, but thankfully my Land Rover was a relatively un-messed with example (meaning everything was thankfully more-or-less as it was when it left the factory), and it was more-or-less possible to see what might have been original line routing and what was just an ad-hoc repair job later.

As well, Peter at 3 Brothers Classic Rovers very kindly took some photos of the pedal box areas in some of his LHD Land Rovers, which enabled some cross referencing.

I don't know if the end result is accurate or not, but it does follow most of the available evidence I could find, and just tried to be logical and safe when in doubt. The brake pipe, as it exits the m/c, could have curved over and gone below the steering shaft (as it does on the clutch m/c), but it would have meant a very tight bend, plus I don't have a wheel that small on my bending tool! The only part that is definitely not standard is the aircraft rubber-cushioned clamp used to hold the clutch slave hose to the bukhead - it was just the right size, and a very high quality part, and does the job perfectly. Also routed the pipes along the curved edge of that part of the bulkhead, to give maximum access to the area behind the engine and things like the flywheel opening.

Not knowing how the pipe lengths would work out, the clutch line was done first, starting from the clutch master cylinder and working towards the rubber hose connection (as there's more flexibility with dimensions at that end), and then the brake line was done starting from the 5-way connection and ending at the brake master cylinder (as I estimated the most excess length would come in useful there).

The two lines are also clamped to the bulkhead at two places between the master cylinders and the clamps visible here. The direction of the brake line clamp, seen on the right, here, was reversed from the original as it was somewhat of an awkward fit as it overlapped the bend in the bulkhead; it also enabled a slightly more direct entry into the 5-way connector (just visible below).

How they were attached (or not!) before:

Friday, September 16, 2011

Seat Box Installed

I imagine it may have to come out again before this project is over, but for now have installed the seat box and some of the other parts. This gives an opportunity to work out what bolts are needed, and test fit whatever else needs to be adjusted.

One change has been to replace the steel fuel line with a nylon one, as I just couldn't find a way to satisfactorily brace the steel version against vibration (and hence wear and cracking, etc.). New fuel tank breather hose is also installed.

With luck the floor panels will be painted this weekend. It's starting to get cooler these days (4 degrees C this morning), but I hope there will be enough warmer days in the next few weeks to finally start to get rid of the well-worn exterior gold colour. Looks as if complete external panel painting may have to wait until next spring, although I hope not.

One change has been to replace the steel fuel line with a nylon one, as I just couldn't find a way to satisfactorily brace the steel version against vibration (and hence wear and cracking, etc.). New fuel tank breather hose is also installed.

With luck the floor panels will be painted this weekend. It's starting to get cooler these days (4 degrees C this morning), but I hope there will be enough warmer days in the next few weeks to finally start to get rid of the well-worn exterior gold colour. Looks as if complete external panel painting may have to wait until next spring, although I hope not.

Thursday, September 15, 2011

Fuel Tank Installed (Again)

Jason at BGM Metalworks did a nice job moving the tank intake tube rearwards (even re-painted the weld area), and now the tank fits as it should. The setup requires a new breather tube, as the old one is now too short, but that's not a big problem.

Tubes now fit, but the forward-extending of the holes in the tub are still necessary.

Tank re-installed, with filler tube attached (Land Rover has a plastic tarp cover on, to protect during painting other parts). Breather tube will go on once it has ben obtained. Triangular brackets sitting on the tank are the lower seatbelt mounts, which will be test fitted and be used to drill the new holes they require in the sills.

Seat belt brackets are just waiting for the seatbox paint to dry for a day or two.

Tubes now fit, but the forward-extending of the holes in the tub are still necessary.

Tank re-installed, with filler tube attached (Land Rover has a plastic tarp cover on, to protect during painting other parts). Breather tube will go on once it has ben obtained. Triangular brackets sitting on the tank are the lower seatbelt mounts, which will be test fitted and be used to drill the new holes they require in the sills.

Seat belt brackets are just waiting for the seatbox paint to dry for a day or two.

Sunday, September 11, 2011

Door Interiors Painted

Door interiors are now painted, and will now wait a few days for a couple of touch ups in areas that somehow only a glossy paint surface can reveal.

Exteriors have been sanded, and are almost ready to paint. It was interesting, in that after a while the outlines of a large losenge-shaped decal began to appear on the outer surface of each door - not the sticker itself, as far as I can see, but a faint remnant of the adhesive. This is most likely from the first owner (1960-1973), who probably used the Land Rover as a commercial vehicle. Given that I'm trying to keep the history of this particular Land Rover alive, in not bringing every single part back to factory-new (many non-painted metal parts, including the galvanizing, have kept their very nice original 'patina', for example, and some areas of original factory paint, even with the nibs and occasional run, have just been given a protective new coat and that's all), plus that the body panels have far too many indications of the Land Rover's extensive life as a hard-working vehicle to be worth stripping completely, I've decided to leave the evidence of the decals as is. Very faint, but there.

Exteriors have been sanded, and are almost ready to paint. It was interesting, in that after a while the outlines of a large losenge-shaped decal began to appear on the outer surface of each door - not the sticker itself, as far as I can see, but a faint remnant of the adhesive. This is most likely from the first owner (1960-1973), who probably used the Land Rover as a commercial vehicle. Given that I'm trying to keep the history of this particular Land Rover alive, in not bringing every single part back to factory-new (many non-painted metal parts, including the galvanizing, have kept their very nice original 'patina', for example, and some areas of original factory paint, even with the nibs and occasional run, have just been given a protective new coat and that's all), plus that the body panels have far too many indications of the Land Rover's extensive life as a hard-working vehicle to be worth stripping completely, I've decided to leave the evidence of the decals as is. Very faint, but there.

Friday, September 9, 2011

On the Ground at Last

After just about a year of work, for a couple of hours almost every day, today the Land Rover stood on its own four wheels again for the first time. There was sufficient weight on the springs so that, when one corner of the vehicle was jacked up, the springs would compress enough to allow the shock absorber to be attached. Once they were all on, down she came for a landing.

This also enabled me to reposition the Land Rover to make working on the left side a little easier.

Once that was done, on went the iconic headlights and a few more items, including the 'bean can'.

This also enabled me to reposition the Land Rover to make working on the left side a little easier.

Once that was done, on went the iconic headlights and a few more items, including the 'bean can'.

Thursday, September 8, 2011

Seat Box Test Fit

Today's task was to test fit the seat box and floorboards. No problems, except to discover the handbrake lever will need to be adjusted as it is presently too low and strikes the bottom of the seat box opening.

Fuel tank is out at BGM Metalworks to have the intake tubes moved rearwards as much as possible. The central outriggers on the new chassis appear to be too far forward (by about 3/4 inch) and the fuel tank can't be moved rearwards enough to install correctly within the tub openings. I had already elongated the tub holes forward in an attempt to let the tank intake tubes pass upwards, but it wasn't enough - it would have required modifying the seat box as well, which I'm not willing to do.

Seatbox and floorboards are in primer only. Steering wheel isn't all the way on, as it was just being used to center the steering arms and test movement along the system.

Fuel tank is out at BGM Metalworks to have the intake tubes moved rearwards as much as possible. The central outriggers on the new chassis appear to be too far forward (by about 3/4 inch) and the fuel tank can't be moved rearwards enough to install correctly within the tub openings. I had already elongated the tub holes forward in an attempt to let the tank intake tubes pass upwards, but it wasn't enough - it would have required modifying the seat box as well, which I'm not willing to do.

Seatbox and floorboards are in primer only. Steering wheel isn't all the way on, as it was just being used to center the steering arms and test movement along the system.

Wednesday, September 7, 2011

Pedals

Installed the pedal boxes this evening, and adjusted the pedal heights as per the manual. All fairly straight forward.

Here, shiny new bolts set off reflections of light similar to water. Original bolts are darker. Pedal return springs not yet installed. Not too happy with the quality of the rubber pedal pads on the brake and clutch pedals. I purchased a second set after a tab snapped off after being bent just a few degrees on the first set, and then tabs broke off on both the new ones! Plus, I can't say I really like the distortion that occurrs when a tab is sucessfully bent. Have installed them for now. Hopefully a better brand can be found.

Here, shiny new bolts set off reflections of light similar to water. Original bolts are darker. Pedal return springs not yet installed. Not too happy with the quality of the rubber pedal pads on the brake and clutch pedals. I purchased a second set after a tab snapped off after being bent just a few degrees on the first set, and then tabs broke off on both the new ones! Plus, I can't say I really like the distortion that occurrs when a tab is sucessfully bent. Have installed them for now. Hopefully a better brand can be found.

Monday, September 5, 2011

'Breakfast', Radiator Installed

Starting to look like a Land Rover more and more. Today the 'breakfast' front panel and radiator were installed. Not too much to it. First placed the shroud over the fan and let it hang there, by itself, as there didn't appear to be too much room if it was included with the 'breakfast' and radiator assembly. Them bolted the 'breakfast' to the radiator, then lifted those units onto the frame and bolted them on. Then attached the shroud to the back of the radiator. Once in place, it was clear the radiator hoses would need to be trimmed to fit!

Prior to that, however, the steering box drop arm and rod ends were all adjusted and finished up, which is why the steering wheel is temporarily installed. This was used to find the center of run.

A few other pieces have been added here and there, too, such as the regulator and fuse boxes, and some of the throttle linkages.

Prior to that, however, the steering box drop arm and rod ends were all adjusted and finished up, which is why the steering wheel is temporarily installed. This was used to find the center of run.

A few other pieces have been added here and there, too, such as the regulator and fuse boxes, and some of the throttle linkages.

Saturday, September 3, 2011

Tailgate; Door Welds; Logos

Finished changing the Defender tailgate fittings to the sturdier ones of the Series 2, and everything has gone together very well (see previous post for what it looked like before). Had to drill one new hole for the center bolt on the hinges, and new holes for the capping rivets. The last thing to do will be the galvanised 'rub strips' that attach to the top surface (when gate is open). These should be riveted on, but as the Defender is double-walled, with a gap in between, as opposed to the Series 2 being just a single sheet, this will take some experimentation. Worse comes to worse they can be attached via screw - but rivets would be nice. Then it'll be time for some Pastel Green paint there, too.

Doors are back from welding at BGM Metalworks. They did a great job, and even voluntarily rebuilt the severely rusted part of the driver's side door frame. Nice service! Now it's on to refining the weld surfaces, treating the remaining surface rust, and then paint.

Doors are back from welding at BGM Metalworks. They did a great job, and even voluntarily rebuilt the severely rusted part of the driver's side door frame. Nice service! Now it's on to refining the weld surfaces, treating the remaining surface rust, and then paint.

Last but not least, have re-painted the logos. There was enough of the original black paint to follow the original demarkation lines very closely. The black stops just short of the top surface, not right at the edge.

Subscribe to:

Comments (Atom)